FOURK ENERGY SERVICES

Pioneering Cuttings Treatment and Fluid Recovery with Innovative Pulsating Technology

OUR SYSTEM

SCAVENGER: A Pressure Differential system that creates a pulsating suction on shaker screens for the best in fluid recovery.

To meet ever-stringent global onshore disposal standards, cuttings must be stripped of free fluid, meaning higher treatment, transportation and disposal costs for operators. The conventional approach to improving separation can cause cuttings attrition that compromises solids removal efficiency and generates formation-damaging fines that hinder drilling fluid performance and can require continuous treatment. In today’s costly operating environment, discarded “free fluid” includes drilling fluids that could be reused in active systems. The SCAVENGER fluid and cuttings separator is a simple retrofit installation delivering enhanced shale shaker performance by creating a suction effect under the screen surface, reaping all the benefits of ultra-fine screen separation efficiency.

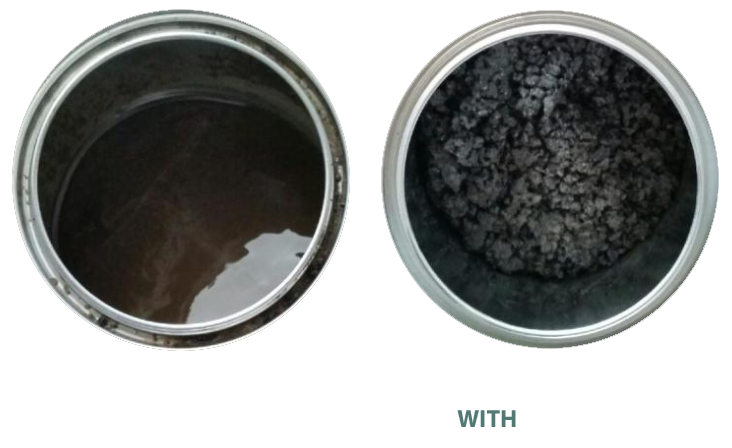

REMARKABLE RESULTS!

No longer do you have to treat and re-treat to ensure your cuttings comply with environmental standards. Installation of the drop in pulsating tray at the flow line is a simple and low-impact operation that requires zero fabrication.

WHAT OUR CUSTOMERS SAY

Operators across Canada are utilizing the SCAVENGER System to optimize there drilling operation.

Terry - Consultant for COGI

“Thanks for the great service. Your shale dryer system is the by far the best one I have used. On this well it salvaged 119m3 of OBM at $1185.00/m3 that is huge money just for the mud alone. That doesn’t factor in the disposal costs for the extra volume the lost mud would have created”

Terry Curley - Athabasca Oil and Gas (Former)

“FourK’s dryer system is the undoubtedly the best recovery system I have used. Ultrafine did not climb, and we maintained the integrity of our mud system. Oil retained on cuttings was cut in half, which has a major factor in the disposal costs, trucking and mix-off the extra fluid would have created”