THE SCAVANGER SYSTEM

The SCAVENGER fluid and cuttings separator is a simple retrofit installation delivering enhanced shale shaker performance by creating a suction effect under the screen surface, reaping all the benefits of ultra-fine screen separation efficiency.

EFFICIENT DESIGN AND OPERATION

An automatic ball valve operates the SCAVENGER system on up to three shakers simultaneously. The system utilizes a lightweight pan, installed as a drop-in, within the shaker bed underneath the last screen on the shaker; an air valve mechanism is attached to the pan and creates a gentle suction force, pulling all the residual drilling fluid from the cuttings surface as they travel towards the discharge end of the shaker.

In addition to enhanced drilling fluid recovery, the SCAVENGER system also generates drier cuttings from the shaker. This reduces waste handling and disposal costs and minimizes crane or heavy equipment movements.

Less Trucking

Slashes transportation, waste disposal costs

Enhances HSE profile

Reduces personnel requirements

Vacuums any heavy gases passing over the screen that could pose a health / safety risk.

Decreases Chemical Consumption

Minimizes or eliminates dilution

Can also vacuum foamed fluids and water wet barite through the screen

Quality Recovered Fluid

Does not deform / fracture or alter cutting, no low gravity solids build up

Oil on cuttings ranges from 3% – 9% wt .

Optimizes Separation Efficiency

Maximizes base fluid recovery

Eliminate SawDust

Reduces overall waste stream

Compatibility

Compatible with OBM, WBM and SBM

Compatable with SWACO, Brandt, Derrick & DFTS Shakers

Reduces Overall Operations Costs

Increases Shaker Screen life by reducing high pressure washing

Does not require a man on

Can pass paint test w/o mix off

Reduces centrifuge operation time.

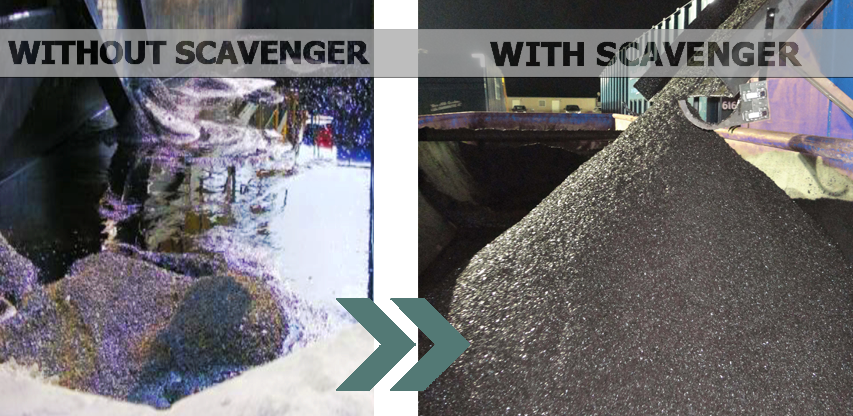

REDUCING FLUID LOSS AT THE SHAKER

Fluid is lost with cuttings as well as just steadily flowing over the screens on its own due to surface tension. In many cases more flows over than is attached to cuttings. Cuttings cannot release oil to the shaker if they are essentially bouncing up and down in drilling fluid. The SCAVENGER fluid and cuttings separator is unique. Rather than applying increased friction and higher G-Forces to a flow-line shaker, it uses suction to gently pull all the residual base fluid from the cuttings surface to head-off attrition and reap all the benefits of ultra-fine screen separation efficiency.

since you no longer have to add expensive and waste-adding treatment chemicals to compensate for the fluid volume lost to the cuttings, dilution rates are reduced dramatically. At the same time, expensive base fluid that once would be discarded is recovered, clearing the way for reuse in the active mud systems.

The Scavenger does all this in a system that is safe, compact, ultra-efficient, and easy to install and operate. The system includes a ball valve pulsar, and mud vacuum.

Recovered fluids stay within shaker flow system, omitting related NPT, the SCAVENGER fluid and cuttings separator eliminates the costs, risks and potential downtime associated with employing ancillary treatment equipment and additional personnel. The SCAVENGER fluid and cuttings separator also delivers cuttings that meet the most stringent environmental standards, such as the paint filter liquids test.

The revolutionary SCAVENGER fluid and cuttings separator technology is your field-proven solution for minimizing waste management costs and optimizing your HSE profile. What’s more, the SCAVENGER fluid and cuttings separator quickly pays for itself by transforming what would be waste into a profitable commodity.

COMPATIBILITY

Manifolds can be modified to fit many shaker types.

Internal and external mounts depending on Shaker Type.

SCAVENGER FLUID AND CUTTINGS SEPERATOR REMOVES CISTLY DRILLING FLUID AND IMPROVES YOUR REVENUE STREAM

Whether distinctly configured for an onshore or offshore application, the revolutionary SCAVENGER fluid and cuttings separator technology is your field-proven solution for minimizing waste management costs and optimizing your HSE profile. What’s more, the SCAVENGER fluid and cuttings separator quickly pays for itself by transforming what would be waste into a profitable commodity.